Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: ZW

Brand: GAOFENG

Impeller Number: Single-Stage Pump

Working Pressure: Low Pressure Pump

Influent Type of Impeller: Single Suction Pump

Position of Pump Shaft: Horizontal Pump

Pump Casing Combined: Horizontal Split Pumps

Mounting Height: Suction Centrifugal

Impeller: Open

Usage: Pump

For Industrial Using: Big Flow Rate

Packaging: Wooden case or Frame steel Case

Productivity: 1100000 sets/year

Transportation: Ocean,Land,Air

Place of Origin: Zigong,Sichuan,China

Supply Ability: 110000 sets/month

Certificate: ISO9001

HS Code: 8413709990

Port: Shanghai,Guangxi,Chengdu

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

ZW Axial-flow Evaporation Circulation Pump

Pumps For Salt Industry, in this area, all the type of pump is a forced circulation pump for the evaporator, it is also an axial Flow Pump. And vertical elbow pumps, this pump has many other styles, and other pumps.

Since 1992, the company has been specialized in the development of forced evaporation circulating pumps, and is committed to promoting the advancement of evaporation and crystallization technology. We have delivered more than 10,000 units to our customers, all of which exceed the standards and customer requirements.

ZW series Axial Flow Pumps include ZWX, ZWXII and ZWQ models, and their design standards are based on GB/T 13008-2013. After long-term research and development investment and technological innovation, excellent performance and reliability are guaranteed.

Owns 8 patent technologies, the comprehensive performance of ZW axial flow pump ranks in top among all the local competitors in China. It is a product of provincial achievement ,and it gained the award of technology progress of China machinery industry. There are plenty of real sales achievements for every single specification from diameter 250 mm to 1500 mm. ZW axial flow pump is widely used as forced circulation pump in the applications of big flow rate with low total head,for example: MVR water treatment, vacuum salt, aluminum oxide, sodium sulfate, chlorine-alkali, sugar making,seawater desalination

Forced Circulation Pump for Evaporators---Hydraulic range and application conditions

The ZW pump is designed to cover a wide range of hydraulic performance applications and to meet the challenges of complex fluid media.

| Medium | Hydraulic parameter range |

| Clean liquid | Flow:150~35000 m3/h |

| Corrosive liquid | Head:8~1.5m |

| High temperature liquid | Pressure:0-1.0MPa |

| Fiber slurry | Temperature:-20~180℃ |

| Viscous liquid | Density:≤1850kg/m3 |

| Containing a large amount of granular slurry | Viscosity:≤600mm2/s |

Common material configuration table as Circulation Pump For Evaporators

| Type | China | USA | Japan | ||||

| GB/T 1220 GB/ 20878 (sectional material) | GB/T 2100(Casting) | UNS | AISI/ ASTM | ACI (Casting) | Code | ||

| Grade | Code | ||||||

| Austenitic stainless steel | 1Cr17Ni7 |

|

| S30100 | 301 |

| SUS301 |

| 0Cr19Ni9 | ZG0Cr18Ni9 | 302 | S30400 | 304 | CF-8 | SUS304 | |

| 00Cr19Ni11 | ZG00Cr18Ni10 | 301 | S30403 | 304L | CF-3 | SUS304L | |

| 0Cr17Ni12Mo2 |

|

| S31600 | 316 | CF-8M | SUS316 | |

| 00Cr17Ni14Mo2 |

|

| S31603 | 316L | CF-3M | SUS316L | |

| 0Cr18Ni11Ti |

|

| S32100 | 321 |

| SUS321 | |

|

| 00Cr20Ni25Mo4Cu |

| N08904 | 904L | |||

| Two-way stainless steel |

| 00Cr22Ni5Mo3N |

| S31803 | 2205 | ||

|

| 00Cr25Ni7Mo4N |

| S32750 | 2507TM | |||

|

|

|

|

|

| |||

|

| 0Cr26Ni5Mo2Cu3 |

|

| CD4MCu | |||

|

Martensitic stainless steel | 0Cr13 |

|

| S41000 | 410S |

| SUS410S |

| 1Cr13 | ZG1Cr13 | 101 | S41000 | 410 | CA-15 | SUS410 | |

| 2Cr13 | ZG2Cr13 | 102 | S42000 | 420 | CA-40 | SUS410J1 | |

| 3Cr13 |

|

|

|

|

| SUS410J2 | |

| 1Cr13Mo |

|

|

|

| CA-15M |

| |

| 1Cr17Ni2 |

|

| S43100 | 431 | CB-30 | SUS431 | |

| Precipitation hardening | 0Cr17Ni4Cu4Nb | ZG0Cr17Ni4Cu4Nb | 501 |

| 17-4PH | CB-7Cu |

|

| 0Cr17Ni7AL |

|

| S17700 | 631 |

| SUS631 | |

| 0Cr15Ni7Mo2AL |

|

|

|

|

|

| |

| Titanium and titanium alloy | TA2 |

|

|

|

|

| |

| TA10 |

|

|

|

|

| ||

| TA9 |

|

|

|

|

| ||

| TA9-1 |

|

|

|

|

| ||

Note: The above table is a list of commonly used materials. If the required materials are not listed in the above table, please contact us.

Chemical Axial Flow pump installation solution

K Hanging installation

Vertical Elbow Pump Model description

The pump and the motor are integrally hinged. The pump and the motor do not need a foundation and are driven by a V-belt.Only the pump with a diameter of 200-500 mm and a motor power of ≤ 45 kW can be installed like this way.

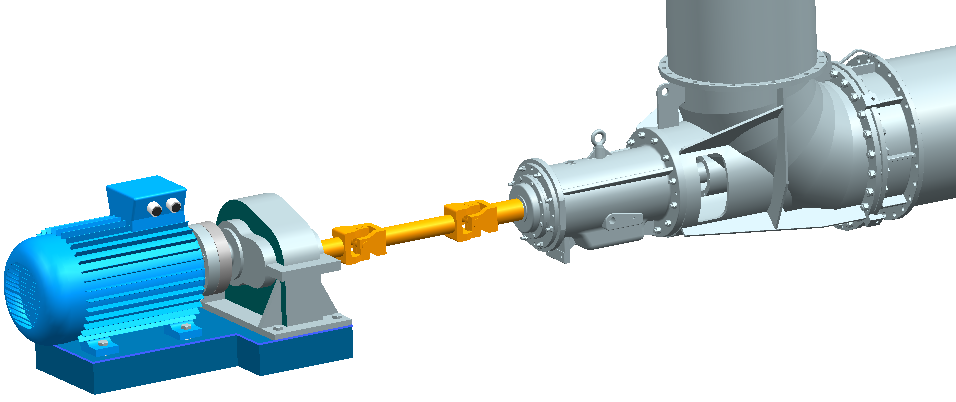

F Horizontal installation for Overflow Elbow Pump

Both the pump and the motor need to be installed with base. The pipe connected to the pump body needs to be provided with expansion joints. The pump and motor can be equipped with V-belt or direct transmission.

Pump + motor + reducer + universal joint

Vertical Elbow Pump---- Products Feature

1. spindle

High-strength spindle after special heat treatment

Flexible choice of integral shaft or butt weld shaft

Reasonable cantilever ratio design, stable and reliable

2. Impeller

Adjustable blades for different working conditions

Slow design technology, no damage to crystals

Cantilever support, quick dis-assembly

3. Pump body

Optimized curved tube runner design with good hydraulic performance

Welding or elbow structure, low operating and maintenance costs

Large machine seal cavity for easy machine sealing and daily

4. Adjust the short section

Adjusted short section of the welded structure, no defects

Adjustable lugs to ensure efficient pump operation

After precision machining, the gap is even

5. Shaft seal system

Efficient packing seal, single-ended mechanical seal, double-ended mechanical seal

Easy to install and replace, no need to measure

6. Bearing housing

Large oil storage space, sufficient bearing cooling and high life

Magnetic oil plug to ensure oil cleaning

Labyrinth + lip seal, high reliability

Integral cast structure, good shock absorption

7. Bearing unit

Equipped with heavy-duty bearings to minimize cost losses caused by unplanned downtime

A variety of bearings are paired for a variety of conditions

The bearing is lubricated and cooled by oil bath

Product Categories : Axial Flow Pumps > Pumps For Salt Industry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.